At Michael Matthews we pride ourselves on being able to not only deliver but exceed our client’s expectations. We have been doing what we do for many years and as a result, have managed to forge relations with many manufacturers, suppliers and diamond dealers all whom are experts in their trade.

If you are looking to create something bespoke or have a piece of jewellery you would like to breathe new life into, we can help.

A Personal Service

We recently undertook a bespoke engagement ring for a client, who wished to surprise his fiancé with a ring he knew she would fall in love with.

The client came to see us at our Bournemouth showroom. He had a budget in mind and a few ideas, along with an image his partner had seen and loved. One of our ring specialists talked him through a few stock mounts and catalogues, in order to establish an idea of design.

Diamond size, grade and clarity were also discussed, to ensure the client understands the options available, for the chosen design and budget.

Image supplied by client

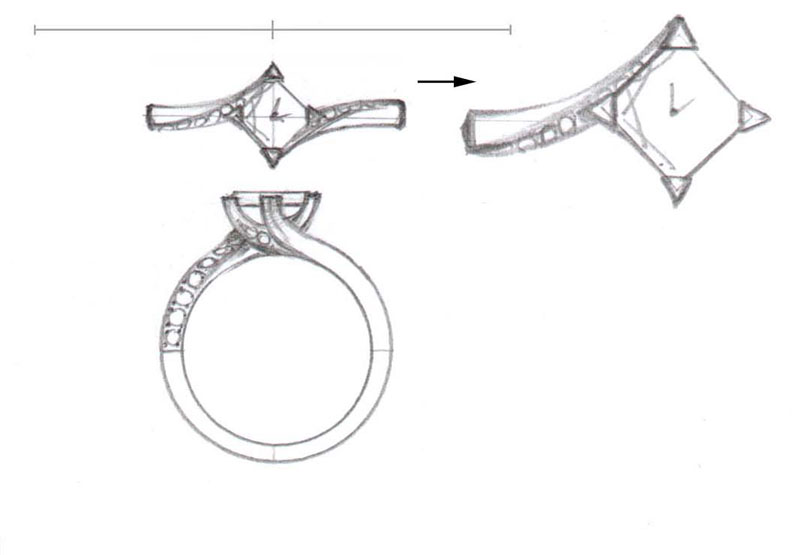

As we wanted to ensure our client got the ring he had envisaged. It was decided that we should create a bespoke ring, using the image supplied as a design guide. Resulting in sketches being made up, ready to send to our manufactures.

Using the original sketch and image, our manufactures produced a CAD (Computer Aided Design). Once our client was happy, we had the mount made.

Once the mount had been created (shown below). We decided that it needed a few tweaks, in order to really fulfil the client’s design brief.

We work alongside a stone setter who also made some suggestions, in order to ensure the diamond could be securely set on the angle the design brief called for.

We instructed our manufactures to tweak the original CAD. At this point, we went through two different designs.

This second CAD was created in order to thin down the shoulders on the original design and a rail was added to the gallery, in order to help secure the diamond.

Third design CAD. The shank has been twisted so the diamond shoulders will now be more visible.

The final mount was then made and given to our stone setter. He then set the diamond and finished the ring off with a polish.